Labor Issues in China’s Fashion Supply

Labor issues explained..

China is the backbone of the global manufacturing economy. From fast-fashion apparel and luxury accessories to smartphones and household goods, nearly one-third of the world’s manufactured products are made in China. For fashion alone, China remains one of the largest exporters of garments, textiles, and accessories worldwide.

But behind low price points and rapid production cycles lies a system built on intense labor pressures. Labor conditions in China’s manufacturing sector don’t stay local, they ripple across global fashion supply chains, shaping costs, timelines, ethics, and brand reputation.

For consumers who care about sustainability and ethics, and for professionals working in fashion sourcing, buying, or marketing, understanding these labor issues is no longer optional, it’s essential.

This blog breaks down the key labor challenges inside China’s manufacturing industry, why they persist, and how they affect the global fashion system.

Millions of workers each day suffer from labor issues in China.

Image via Made In China

China: The World’s Manufacturing Center

China’s dominance in manufacturing is unmatched.

Produces about one-third of all manufactured goods globally

Employs hundreds of millions of factory workers

Serves nearly every major fashion and electronics brand

Most factory workers are rural migrants who leave their hometowns for industrial cities like Shenzhen, Guangzhou, and Shanghai. While factory jobs often pay more than agricultural work, they come with long hours, limited protections, and separation from family.

Because so many global brands rely on Chinese manufacturing, labor issues in these factories affect product pricing, production speed, and brand ethics worldwide.

China’s manufacturing dominance did not happen overnight. Decades of government investment in infrastructure, export zones, ports, and industrial clusters helped create one of the most efficient production systems in the world. Cities such as Shenzhen and Guangzhou evolved into global manufacturing hubs where factories, suppliers, and logistics providers are concentrated in one region.

For fashion brands, this concentration lowers costs, reduces lead times, and allows rapid scaling. A design approved one week can be produced, packaged, and shipped within days. While this system benefits brands and consumers, it places constant pressure on workers to meet accelerated timelines with little flexibility or protection.

As global demand for fast fashion increased, speed became just as important as cost. This shift intensified labor strain, turning human labor into a tool for rapid turnaround rather than sustainable employment.

China on a map.

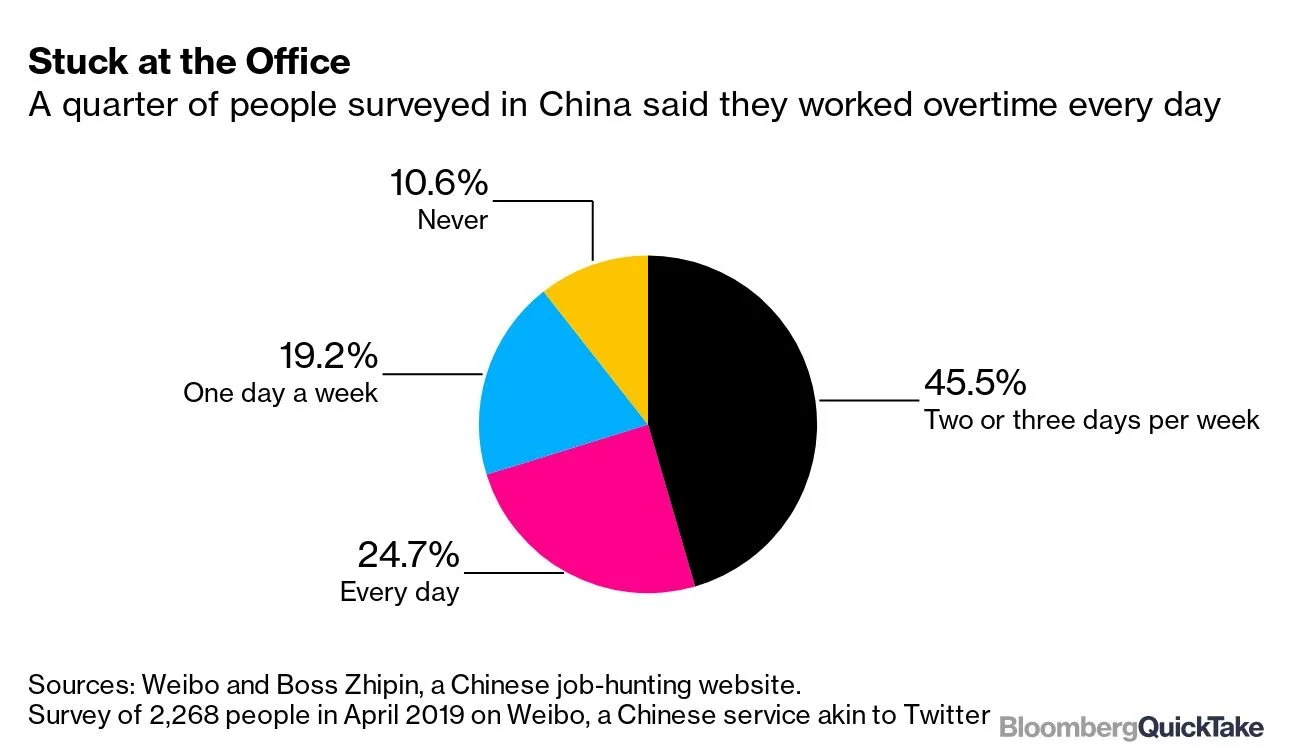

Excessive Overtime Is the Norm, Not the Exception

Chinese labor law limits work to 44 hours per week, but in reality, many factory workers report:

60–100 hour workweeks

Mandatory overtime during peak seasons

Few days off during production rushes

Investigations show Shein suppliers often push employees to 75-hour weeks, violating labor laws.

This issue is especially visible in electronics and fast-fashion factories, where trends change weekly and brands demand rapid turnaround.

Workers often describe overtime as “voluntary,” but refusal can lead to:

Reduced bonuses

Shift reassignment

Job loss

For many, overtime isn’t optional, it’s the only way to earn enough to survive.

Peak production seasons intensify overtime demands even further. During holiday launches or major online sales, workers report shifts lasting 12 to 14 hours per day for consecutive weeks. These extended schedules leave little time for rest or recovery, increasing physical exhaustion and risk of injury.

Long working hours also take a toll on mental health. Worker interviews frequently mention chronic fatigue, stress, and anxiety caused by nonstop production pressure. When overtime becomes standard rather than exceptional, workers lose the ability to control how their time and labor are valued.

Survey taken in China proving how much they work overtime.

Image via Bloomberg

Low Base Wages vs. Rising Urban Living Costs

Base wages in many manufacturing regions do not keep up with rising living expenses, especially in urban areas.

Key challenges include:

Housing costs

Food inflation

Healthcare access

Major suppliers such as Foxconn, which produces goods for global tech and fashion brands, have faced ongoing criticism for low base pay paired with intense overtime requirements.

Workers often live in crowded dormitories provided by factories, a system that keeps labor costs low but reinforces worker dependence on employers for housing and income.

Urban inflation magnifies wage inequality. While wages may technically meet legal minimums, they often fail to cover basic expenses without overtime pay. Transportation costs, food prices, and healthcare fees continue to rise, leaving workers financially vulnerable even when fully employed.

Many workers also send money home to support family members in rural regions. This reduces disposable income and makes saving nearly impossible. Financial insecurity reinforces overtime dependence, turning survival into a cycle tied directly to excessive labor.

Key challenges specifically in urban areas.

Image by Alexandra Oakland via Canva

Harsh Management and High-Pressure Production Targets

Many factories operate under military-style management systems, especially in fast-fashion and mass electronics production.

Common worker complaints include:

Strict surveillance on factory floors

Punishments for mistakes or missed quotas

Unrealistic daily output targets

Limited breaks during long shifts

Investigative reports have frequently cited Shein-linked factory environments as examples of high-pressure systems where speed and volume are prioritized over worker well-being.

This structure is designed to maximize efficiency, but often at the cost of physical and mental health.

Worker Safety Remains a Serious Concern

Although safety regulations exist, enforcement is inconsistent.

Common safety risks include:

Exposure to toxic chemicals

Poor ventilation systems

Inadequate protective equipment

Repetitive strain injuries

In electronics manufacturing, workers may handle solvents and heavy metals without sufficient training or gear.

While conditions have improved compared to past decades, accidents and long-term health impacts still occur, especially in factories under intense production pressure.

Safety risks are often highest in subcontracted factories operating outside direct brand oversight. These facilities may skip training, delay equipment repairs, or ignore maintenance to meet deadlines. In these environments, productivity is prioritized over safety.

Long-term exposure to hazardous materials can lead to chronic health conditions that go untreated. Without sufficient healthcare access or compensation systems, injuries often become personal burdens rather than corporate responsibilities.

Worker safety is a continued concern

Image by Alexandra Oakland via Canva

Child Labor in Smaller, Unregistered Workshops

Large, internationally audited factories rarely employ children. However, child labor still exists in smaller, unregistered workshops, particularly in rural or subcontracted settings.

Some factories label underage workers as:

“Student workers”

“Intern trainees”

Despite the label, many perform the same tasks as adult workers with fewer protections and lower pay.

These subcontracting layers allow brands to distance themselves while still benefiting from low-cost labor.

Young children in harsh working conditions.

Image via UNICEF

Migrant Workers and Systemic Discrimination

Most factory workers are migrants from rural provinces. Under China’s hukou (household registration) system, migrant workers often lack access to:

Urban healthcare

Public education for children

Housing subsidies

Social security benefits

This creates a workforce that is:

Essential to the economy

Under-protected by the system

Easily replaced

The hukou system severely limits upward mobility by tying social services to birthplace rather than employment location. Workers may spend decades in cities without gaining access to benefits.

For fashion brands, reliance on a marginalized labor force lowers costs while masking systemic inequality. Migrant workers remain essential yet undervalued within China’s manufacturing economy.

Why This Matters to Fashion Consumers and Brands

For Consumers

If a garment feels cheap, arrives quickly, and costs less than lunch, someone else paid for that convenience.

Understanding labor conditions helps consumers:

Make informed purchasing decisions

Support ethical brands

Demand transparency

For Fashion Brands

Labor issues create:

Reputational risk

Regulatory scrutiny

Supply-chain instability

Brands that ignore factory conditions risk backlash, boycotts, and loss of consumer trust.

Companies like Shein constantly take advantage of their workers to put out products fast and cheap to their customers.

Image via Business of Fashion

How the Fashion Industry Is Responding

While challenges persist, change is slowly emerging:

Third-party factory audits

Supplier codes of conduct

Digital Product Passports

Supply-chain mapping technology

Global pressure is forcing brands to reevaluate supply chains. EU regulations and growing transparency expectations in the U.S. demand proof of ethical sourcing. However, meaningful reform requires enforcement, not just documentation.

What Ethical Progress Actually Looks Like

Livable base wages

Real enforcement of labor laws

Reduced reliance on mandatory overtime

Worker union protections

Transparent supply chains

True reform requires systemic change, not just press releases.

Real enforcement of labor laws: a part of the ethical progress.

Image via Rush & Nicholson

Final Thoughts: The Cost of Cheap Fashion

China’s manufacturing industry keeps the global fashion system running, but at a human cost that often goes unseen.

As consumers become more sustainability-minded and regulations increase worldwide, labor conditions will continue to shape the future of fashion.

Choosing better doesn’t mean choosing perfectly.

It means choosing awareness, accountability, and transparency.

References

China Labor Watch. (2025, July). Slow justice fast fashion: Labor conditions in Shein’s supply workshops. China Labor Watch. https://chinalaborwatch.org/wp-content/uploads/2025/07/1.-SHEIN-report-28-Jul.pdf

Business & Human Rights Resource Centre. (2025, January 13). BBC investigation reveals Shein suppliers’ workers face 75-hour work weeks & low wages. Business & Human Rights Resource Centre.

IOSH Magazine. (2025, January 17). BBC investigation raises concern over labour conditions in garment factories. IOSH Magazine. https://www.ioshmagazine.com/2025/01/17/bbc-investigation-raises-concern-over-labour-conditions-garment-factories-supply-chinese

Earth Day. (2025, September 12). Beneath the seams: The human toll of fast fashion. Earth Day Network. https://www.earthday.org/beneath-the-seams-the-human-toll-of-fast-fashion/

Supply Chain World. (2025, January 7). Fast-fashion under fire: Shein accused of wilful ignorance. Supply Chain World.

https://scw-mag.com/news/fast-fashion-under-fire-shein-accused-of-wilful-ignorance/

China Labor Watch. (2025, September). Foxconn report 2025: Apple’s dependence on China in its supply chain. China Labor Watch. https://chinalaborwatch.org/wp-content/uploads/2025/09/Foxconn-Report-2025-China-Labor-Watch.pdf

China Daily. (2024, August 3). Reform makes it easier for migrants to gain city hukou. China Daily. https://english.www.gov.cn/news/202408/03/content_WS66ad8b4fc6d0868f4e8e9b67.html

Backlinks

Fast Fashion & Sustainability

https://www.earthday.org/beneath-the-seams-the-human-toll-of-fast-fashion/

Shein Labor Investigations (China Labor Watch Report)

https://chinalaborwatch.org/wp-content/uploads/2025/07/1.-SHEIN-report-28-Jul.pdf

BBC Investigation on Shein Suppliers (Business & Human Rights Resource Centre)

Factory Safety Concerns (IOSH Magazine Report)

Supply Chain Ethics (Supply Chain World)

https://scw-mag.com/news/fast-fashion-under-fire-shein-accused-of-wilful-ignorance/

Foxconn Labor Practices (China Labor Watch Report)

https://chinalaborwatch.org/wp-content/uploads/2025/09/Foxconn-Report-2025-China-Labor-Watch.pdf

Migrant Worker Hukou System (China Daily Government Reform Article) https://english.www.gov.cn/news/202408/03/content_WS66ad8b4fc6d0868f4e8e9b67.html